PROCESSES OF RECOMBINANT DNA TECHNOLOGY

Recombinant DNA Technology: Step-by-Step Overview

Recombinant DNA technology involves a series of systematic steps for genetic manipulation and protein production.

Isolation of Genetic Material (DNA):

- DNA, the genetic material, needs to be in pure form for manipulation.

- Cell membranes are broken to release DNA along with other macromolecules.

- Enzymes like lysozyme, cellulase, or chitinase used for cell lysis.

- DNA purification involves removal of RNA, proteins, and other contaminants.

- Purified DNA precipitates with chilled ethanol.

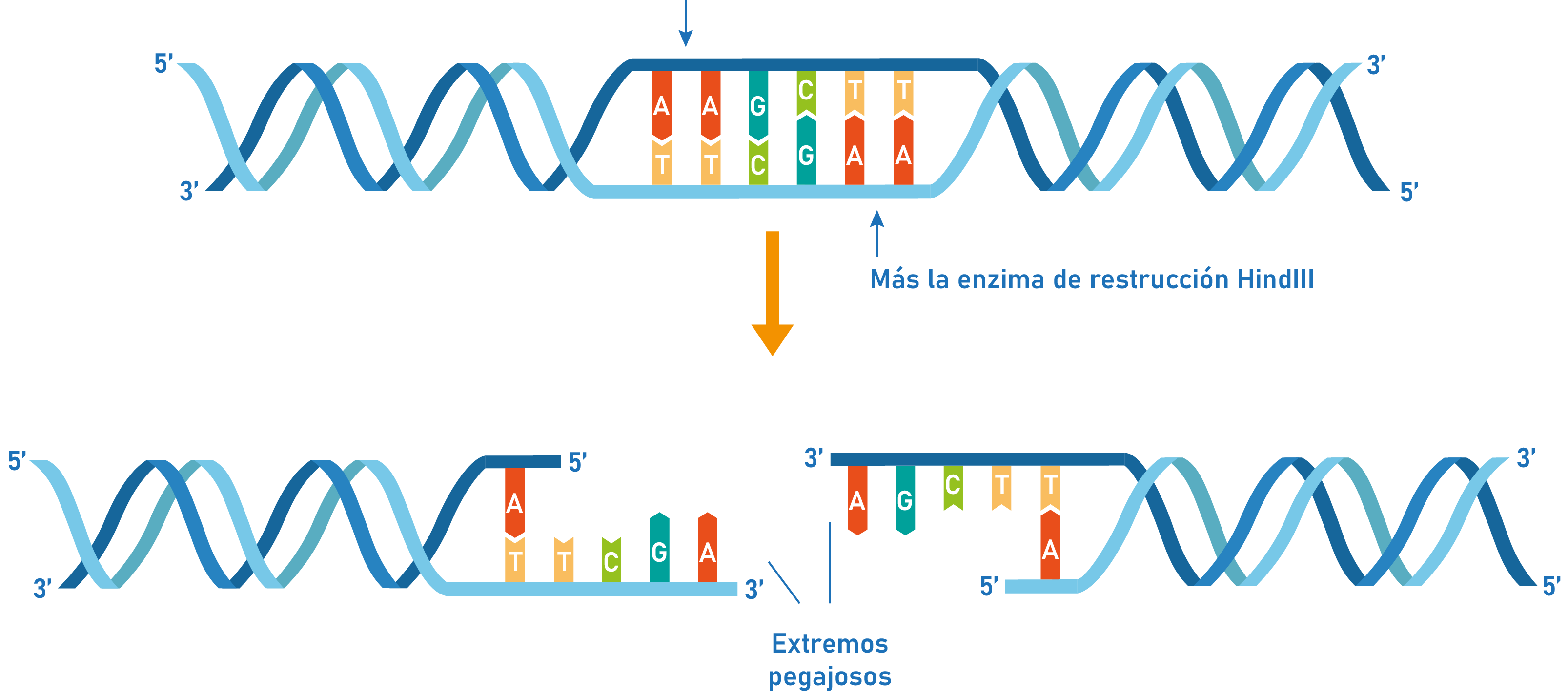

Cutting DNA at Specific Locations:

- Restriction enzyme digestion performed on purified DNA.

- Agarose gel electrophoresis checks digestion progress.

- Vector DNA also subjected to the same process.

Joining of DNA (Ligation):

- Gene of interest from source DNA and cut vector mixed.

- Ligase added to facilitate the joining process.

- Resulting in the formation of recombinant DNA.

Amplification of Gene using PCR:

- Polymerase Chain Reaction (PCR) for synthesizing multiple copies of the gene.

- Two sets of primers and DNA polymerase used for in vitro amplification.

- Billion-fold amplification achieved using a thermostable DNA polymerase.

Insertion of Recombinant DNA into Host:

- Ligated DNA introduced into competent recipient cells.

- Cells take up recombinant DNA.

- Selection based on antibiotic resistance genes.

- Transformed cells identified and cultured.

Obtaining the Foreign Gene Product:

- Expression of foreign genes under suitable conditions.

- Recombinant DNA multiplied within host cells.

- Aim is to produce a desirable protein.

- Large-scale production achieved using bioreactors.

Bioreactors for Large-Scale Production:

- Vessels facilitating biological conversion of raw materials into products.

- Stirred-tank reactors or alternative systems for optimum growth conditions.

- Agitator system, oxygen delivery, foam control, temperature, and pH control systems present.

Downstream Processing:

- After biosynthetic stage, product undergoes downstream processing.

- Separation and purification processes.

- Formulation with preservatives.

- Clinical trials and quality control testing.

Final Product Preparation:

- Product ready for marketing after downstream processing.

- Quality control ensures product efficacy and safety.

- Formulation and testing vary based on the specific product.

Amplification of Gene of Interest using PCR

Polymerase Chain Reaction (PCR) is a powerful technique for in vitro amplification of specific DNA segments.

Principle:

- PCR replicates a targeted DNA segment using DNA polymerase enzyme.

- Utilizes synthetic oligonucleotide primers, DNA template, and nucleotides.

Procedure:

Denaturation (94-98°C):

- DNA template heated to separate double-stranded DNA.

- High temperature breaks hydrogen bonds, yielding single-stranded DNA.

Annealing (50-65°C):

- Reaction cooled to allow primers to bind to complementary sequences on single-stranded DNA.

- Temperature critical for primer specificity.

Extension (72°C):

- DNA polymerase synthesizes new DNA strands using primers.

- Reaction temperature optimized for enzyme activity.

Cycle Repetition:

- Repeated cycles (typically 20-40) of denaturation, annealing, and extension.

- Each cycle doubles the amount of target DNA.

Thermostable DNA Polymerase:

- Enzyme resistant to denaturation temperature.

- Taq polymerase, isolated from Thermus aquaticus bacterium, commonly used.

Application:

- Gene amplification for various purposes, including cloning, sequencing, and analysis.

- Diagnostic tool for detecting genetic diseases or pathogens.

Advantages:

- Rapid and efficient amplification.

- Minimal DNA requirement.

- Versatile application in molecular biology.

Limitations:

- Error-prone, may introduce mutations.

- Sensitivity to reaction conditions.

- Limited fragment size (<5 kb) in traditional PCR.

Variations:

- Reverse Transcription PCR (RT-PCR) amplifies RNA by first converting it into complementary DNA (cDNA).

- Quantitative PCR (qPCR) measures DNA concentration during amplification.

BIOREACTOR

| Bioreactor Type | Description | Functionality | Components |

|---|---|---|---|

| Simple Stirred-Tank Bioreactor | – Cylindrical or curved base. – Equipped with a stirrer/agitator. | – Even mixing of nutrients and oxygen. – Suitable for various cell cultures. | – Agitator system. – Temperature control. – Sampling ports. |

| Sparged Stirred-Tank Bioreactor | – Similar to a stirred-tank with additional features. – Sterile air bubbles sparged into the culture. | – Combines mechanical stirring with air sparging for improved oxygen transfer. – Suitable for aerobic cultures. | – Agitator system. – Air sparging system. – Temperature and pH control. – Foam control. |